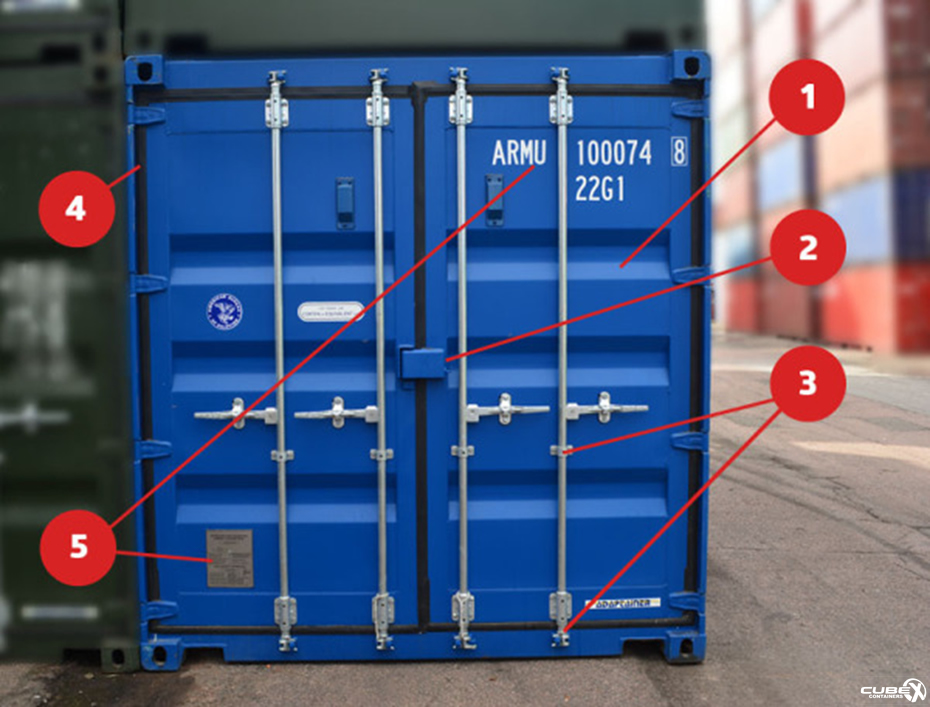

Shipping Container Door

1. Doors

There are two door leaves each fabricated from two vertical rolled hollow sections and 2 horizontal c section members. The frame is infilled with corrugated steel panelling.

These are normally attached to the rear corner posts each with four drop forged steel hinge blades. The blades allow 270 degree opening which allow the doors to swing back against the container side wall.

2. Lockbox

The lock box is a steel box welded to the right hand door which overlaps a staple welded to the left hand door. A container padlock, can then be attached inside the lock box through the staple and is then protected from direct attack, hindering attempts to gain entry to the container.

3. Lockrods, cams and keepers

Each door is fitted with two vertical lock rods to enable opening, closing and locking of the doors.

At the end of each lock rod (top and bottom) is a cam welded in place which engages with knuckles, also known as cam keepers.

The action of engaging the cams to the keepers forms an anti-racking function.

4. Rubber gaskets

Rubber gaskets are fitted to the container doors during the manufacturing process and prevent water ingress.

5. ISO markings and CSC plate

ISO markings and a consolidated data plate allow worldwide intermodal transport when left in place and updated as necessary.